Tsis siv neeg pob zeb diamond qauv willow nplooj qauv hlau embossing tshuab

Product Description

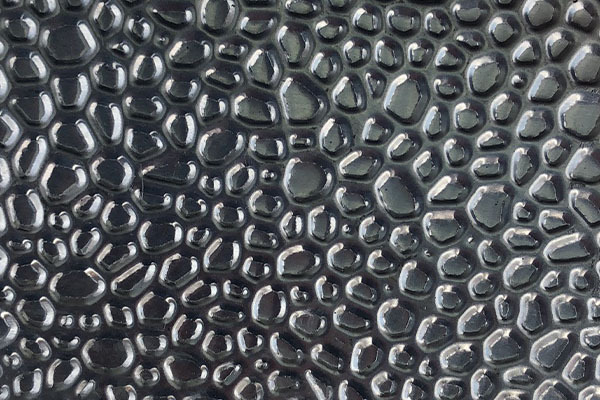

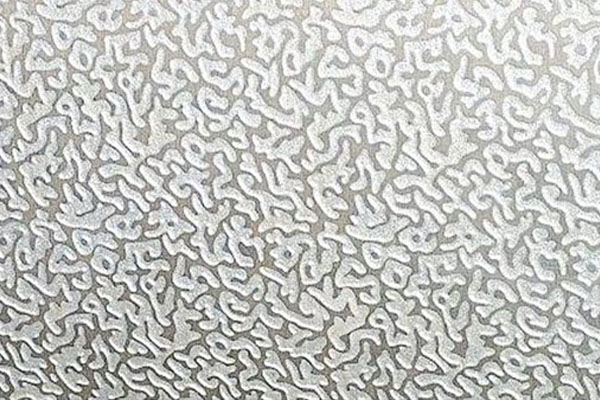

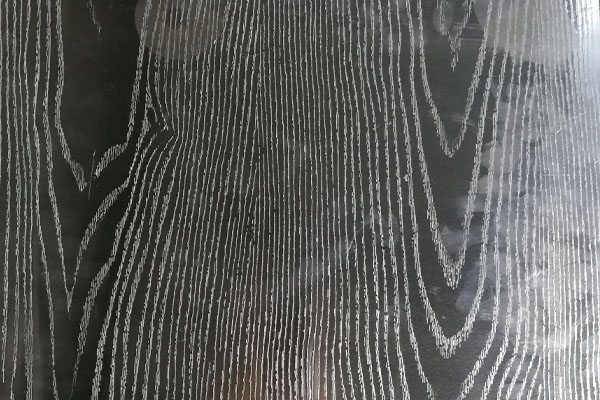

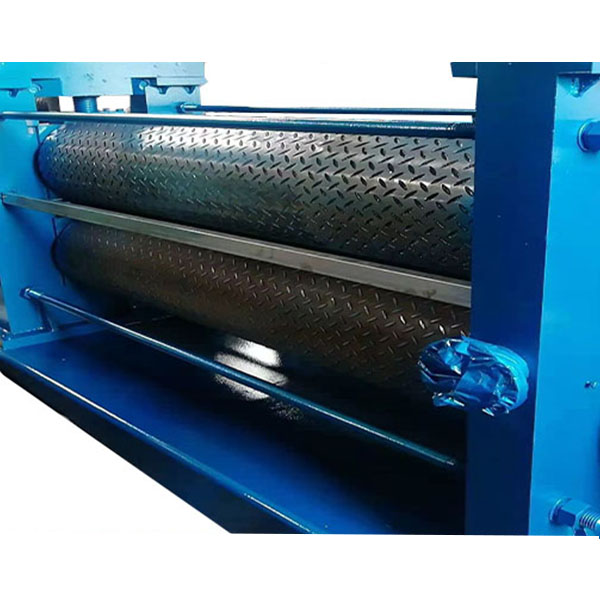

Hlau embossing tshuab yog ib yam ntawm cov cuab yeej siv rau embossing thiab sib sau cov hlau nyias xws li txhuas daim hlau, xim hlau daim hlau, tooj liab daim hlau, thiab stainless hlau daim hlau.Lub tshuab hlau embossing muaj xws li ib lub thav duab, ib daim ntawv qhia cov menyuam, cov menyuam embossing, cov khoom sib kis thiab cov cuab yeej hloov kho.Cov menyuam phau ntawv qhia, cov menyuam embossing thiab cov khoom siv kis tau tus mob yog tag nrho ruaj khov rau ntawm tus ncej, thiab muaj ob txoj kev qhia rollers.Lawv feem ntau nyob ntawm ob sab ntawm cov menyuam lub cev ntawm cov menyuam embossing.Lub embossing rollers muaj ob lub embossing rollers tso rau saum ib qho.Cov menyuam ncej ntawm embossing rollers muab tso rau hauv qab yog txuas nrog cov khoom sib kis, thiab ob lub embossing rollers yog teem rau ntawm kev kho cov cuab yeej kho qhov sib txawv ntawm ob embossing rollers.Lub tshuab hlau embossing yog yooj yim hauv cov qauv, siv tau yooj yim, tsis tshua muaj nqi ntau lawm, thiab kev siv hluav taws xob tsawg.Qhov saum npoo ntawm cov menyuam embossing muaj cov qauv meej kom ntseeg tau tias embossing zoo ntawm cov ntawv hlau.

Khoom Parameters

1.Precision sib tsoo rau tshem tawm burrs los ntawm lub puab lub qhov ntawm lub workpiece

2. Tshem tawm cov oxide zaj duab xis

3.Tiav nto polishing kho cov roj stains

4.Ua kom siab chav tsev siab

5.Qhov sib txawv loj hauv kev khiav hauj lwm ceev

6 me me radial loj

7.High tso zis hwj chim, kev ua haujlwm yooj yim thiab siv tau yooj yim

8.Reliable zoo thiab kev ua haujlwm siab

9.Ib qho yooj yim installation thiab siv sij hawm luv luv

10.Vibration thiab tawg kuj, kev pab lub neej ntev

Cov duab ntxaws

Nrog lub peev xwm loj thauj khoom thiab ntau tus qauv pwm, hlau profiles ntawm qee qhov tshwj xeeb tuaj yeem raug nias rau hauv cov qauv nrog ntau hom.Siv cov cuab yeej hloov pauv hloov pauv hloov pauv hloov pauv hloov pauv, lub cycloidal pinwheel reducer tuaj yeem raug thiab paub ceev nrawm hloov pauv kom tau raws li qhov yuav tsum tau siv.Nws muaj ib tug anti-wrinkle dov mechanism thiab ib tug electromagnetic clutch tiv thaiv ntaus ntawv.Tom qab embossing los ntawm lub tshuab no, nws tuaj yeem txhim kho nws qhov zoo nkauj zoo nkauj.Nws yog ib qho khoom siv zoo tshaj plaws rau kev ntim khoom thiab luam ntawv kev lag luam los txhim kho cov khoom zoo, ntxiv dag zog rau kev tiv thaiv cov khoom cuav, thiab tiv thaiv cov cim lag luam.